Factors to Consider When Selecting a PCB Design Company

Selecting the right PCB design partner is crucial for the success of your electronic product. Look for a company with extensive experience, technical expertise, and a customer-centric approach. A&P PCB Material Supply offers comprehensive PCB design services to help bring your vision to life.

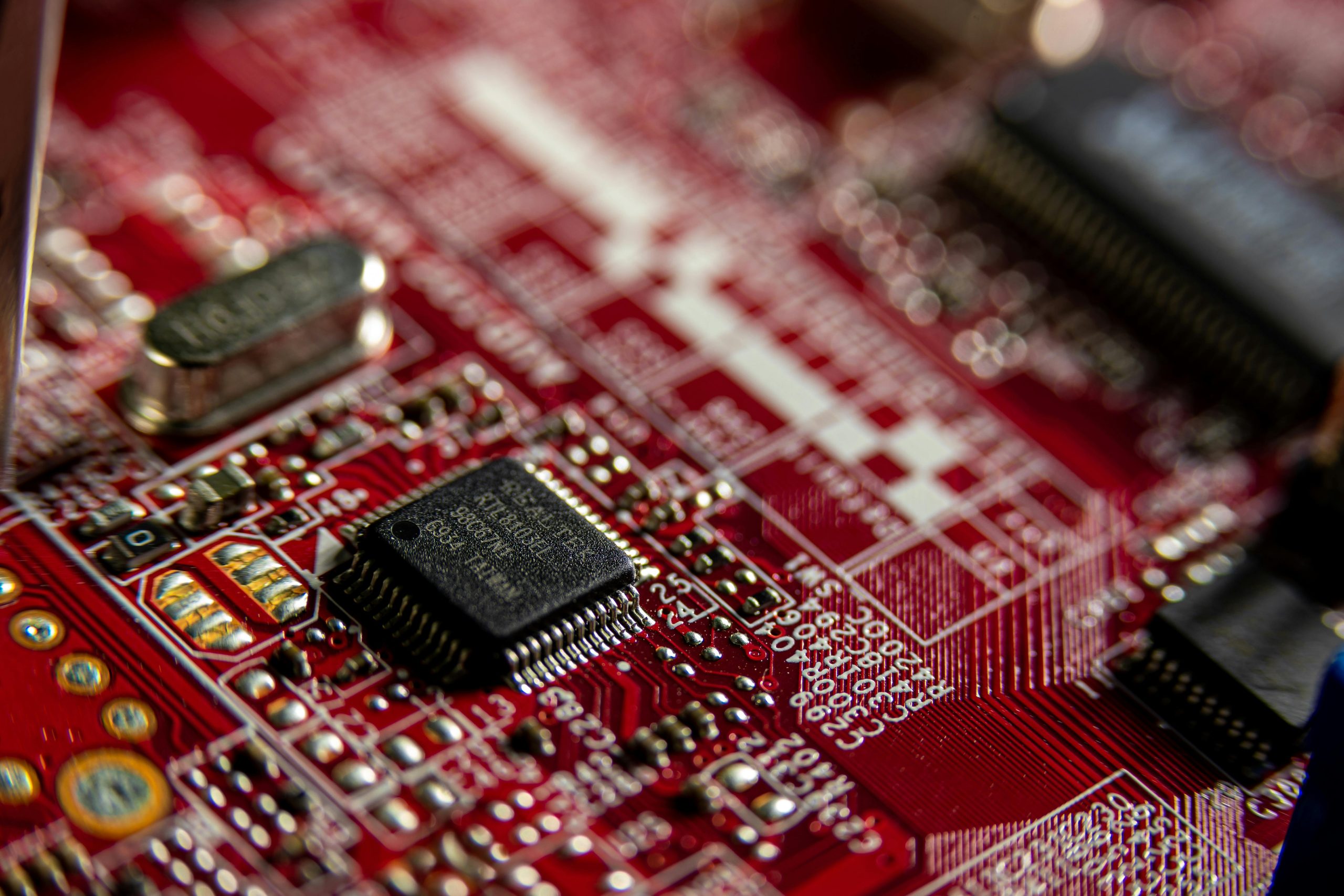

PCB SOLUTIONS

A & P Material Supply offers a wide range of PCB solutions, from simple single-layer boards to advanced multi-layer and HDI designs.

MINIMIZE YOUR COSTS

We work closely with our clients to understand their unique requirements and provide customized solutions that optimize functionality while minimizing costs.

SOLUTIONS THAT LAST

We stay at the forefront of technological advancements in the PCB industry, constantly investing in the latest equipment and processes to deliver cutting-edge solutions.

Important factors in choosing a partner

Company's Experience and Expertise

When evaluating potential PCB design partners, it's crucial to consider their technical expertise and experience in the field. Look for a company with a deep understanding of PCB design principles, the latest technologies, and industry best practices.

A PCB design firm with a diverse portfolio spanning various sectors and applications is likely to have a more versatile skill set and a broader knowledge base to draw from. This exposure to different design challenges can enable them to bring innovative solutions and fresh perspectives to your project.

Quality of Materials Used

The quality of the materials used in PCB design and manufacturing is a critical factor that can significantly impact the performance, reliability, and longevity of the final product. A reputable PCB design firm will guide clients in selecting the optimal materials and components for their specific application, considering factors such as electrical requirements, thermal management, and cost.

In addition to material and component selection, a top-notch PCB design company will have a robust design for manufacturability (DFM) process in place. DFM involves designing the PCB in a way that ensures efficient and reliable manufacturing, taking into account factors such as component placement, routing, and testing.

Design Capability and Flexibility

Flexibility is key in a PCB design partnership. The right company should be able to work closely with your team, incorporating your feedback and making necessary changes throughout the design process. They should also be open to customizing their services to fit your project's scope, timeline, and budget, rather than offering a one-size-fits-all approach.

In addition to technical capabilities, it's important to assess a PCB design company's ability to handle the entire design process, from concept to manufacturing. A full-service provider can streamline your development process, reducing the risk of errors and delays that can occur when working with multiple vendors.

Customer Reviews and Feedback

When selecting a PCB design company, customer reviews and feedback can provide valuable insights into the quality of their services and the level of satisfaction among their clients. Positive testimonials from previous customers can instill confidence in a company's ability to deliver high-quality designs and meet project requirements.

In addition to customer reviews, case studies showcasing a company's past projects can demonstrate their experience and capabilities across various industries and applications. These case studies can provide insights into how the company approaches challenges, incorporates client feedback, and delivers results that meet or exceed expectations.

A Trusted PCB REPAIR PARNTER

At A&P PCB Material Supply, we pride ourselves on being the right choice for all your PCB design needs. Our extensive experience and expertise in the field, combined with our commitment to using only the highest quality materials and advanced techniques, sets us apart from the competition. With a team of seasoned professionals who have worked on a wide range of projects across various industries, we bring a wealth of knowledge and a versatile skill set to every project we undertake. Our designers stay up-to-date with the latest technological advancements and continuously update their design tools and software to ensure that we can leverage cutting-edge techniques and optimize your PCB design for performance, reliability, and manufacturability.

In addition to our technical capabilities, we also offer comprehensive support throughout the entire design process. Our team works closely with clients to understand their unique requirements and provide expert recommendations at every stage. We have a dedicated design for manufacturability (DFM) team that uses advanced tools and techniques to optimize designs for efficient and reliable manufacturing, helping our clients avoid costly issues and delays down the line.

At A&P PCB Material Supply, we understand that exceptional customer service is the foundation of a successful PCB design partnership. Our team is dedicated to working closely with clients throughout the entire design process, ensuring that their unique requirements are met and their expectations are exceeded. We believe in fostering a collaborative partnership with our clients, working together to develop innovative solutions that push the boundaries of what's possible in PCB design.